A pyrolysis recycles waste and produces fuel. The waste can be anything, such as plastic, rubber, or oil sludge. Imagine turning waste that usually causes pollution into something that can keep the environment clean. This way you will be able to reduce the pressure on natural resources. The fuel produced by a pyrolysis plant can be used to run vehicles or operate machines.

For starters, it may seem like a massive investment. But you need to see the positives of this plant. It can help you make thousands by producing fuel that you can sell later. Moreover, the plant is expensive for a reason. Converting materials like worn-out tires and scrap plastic is never easy. But imagine the plant’s capacity that can convert these materials into fuel within a few hours. It’s the mechanism of the plant or its working principle that makes it so expensive. Here are a few factors that contribute to the pyrolysis plant cost:

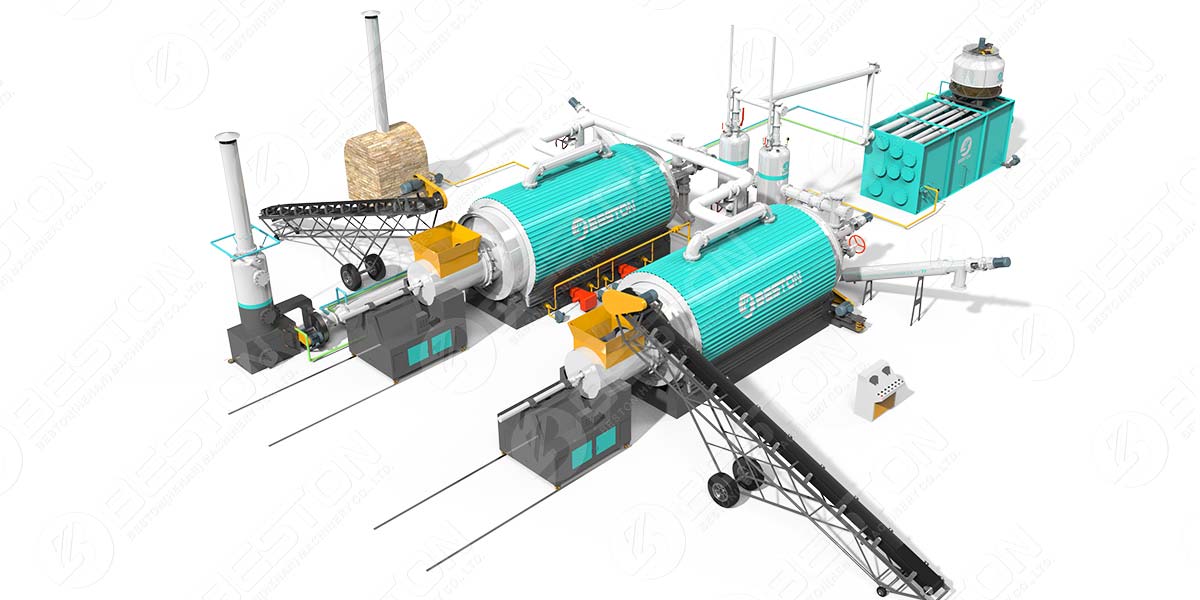

Newly Design Pyrolysis Machine With Two Reactor

1. First of all, a pyrolysis plant has a huge capacity. This means you can put a massive quantity of waste materials in each batch. The price of the plant depends on how much waste materials it can take. The higher the intake, the more fuel the plant can make in one batch. On the other hand, the performance of the plant also depends on the intake. A plant that doesn’t work at its optimum level may not be able to consume its highest capacity of waste materials.

It’s better to compare the performances of different models before you finally buy a pyrolysis machinery. Pay more attention to the performance of the plant instead of merely focusing on the intake capacity.

3. The output of the plant plays a crucial role in determining its performance. A waste tyre pyrolysis plant that produces the maximum amount of fuel is worth investing in. It’s wise to go through three things before you buy a pyrolysis plant: the intake capacity, performance, and output. There should be a balance among these three factors.

BLJ-16 Pyrolysis Plant In Paraguay

The condenser and reactor are two crucial parts of a pyrolysis plant. They are responsible for melting the raw materials and turning them into fuel. Compare the efficiency of the condenser and reactor before you buy the plant.

Will the cost of pyrolysis plants go down anytime soon? No one knows the answer. The reactor and condenser are the most expensive parts and unless manufacturers curb their prices, you can’t expect the cost of pyrolysis plants to go down. Check the mini pyrolysis plant here.