If you are in the egg producing business, you know how important it is to get your fresh eggs to your customers in a timely manner. Eggs need to be protected by special egg trays that can provide protection for each egg in the tray so they will not break during transport. You can order ready-made egg trays from a supplier, but there is always a risk of the tray order not arriving on time which can delay the egg delivery to your customers. A better way would be to make the egg trays yourself. You can start by contacting reliable egg tray making machine suppliers, such as Beston.

Egg Tray Machine Customers and Supplier

Beston supplies egg tray making machines all over the world. Countries around the world use eggs as a food staple and as an ingredient in making all types of food products. Egg producers around the world all face the same challenges: how to deliver their eggs to their clients without breakage? The only answer is by putting the eggs in trays that have the right sized cups so each egg will be protected from all sides.

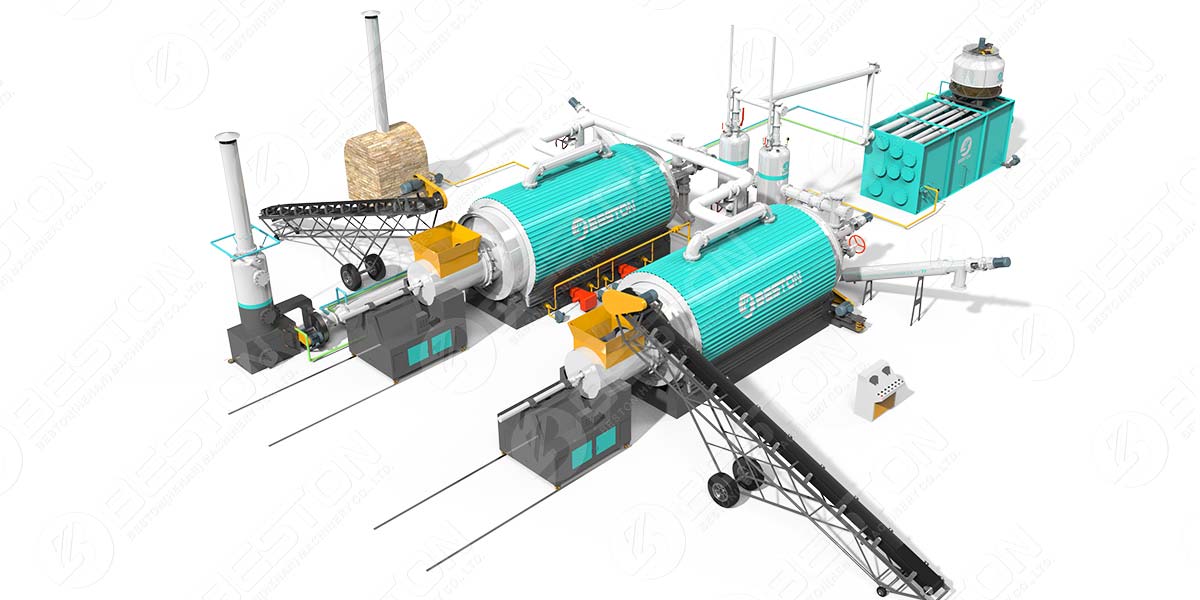

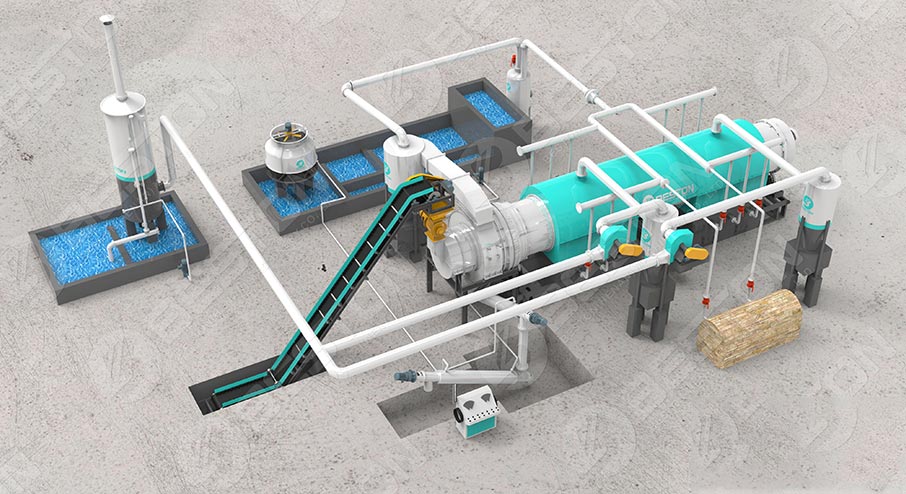

The paper tray making machine can make trays of all sizes. All you have to do is to use different size molds. For example, if you produce both chicken eggs and quail eggs, you would use the mold that have the smaller egg cups for the quail eggs and the mold designed for chicken eggs for the chicken eggs. With one egg tray machine, you can make egg trays for any type of eggs by using different molds.

Affordable Egg Tray Making Machine for Sale

It is important to work with egg tray machine manufacturers who understand what the egg producers need. Beston has a global reputation of supplying high quality and reliable egg tray machines. Egg producers are very happy that they can control the making of the egg trays themselves and no longer have to rely on the delivery of ready-made trays. They see that making their own egg trays can lower their operating costs in the long run because it costs very little to make the egg trays. The materials used in the tray making, which are water and recycled paper products, cost practically nothing.

The egg tray making process is also good for the environment because after the customer discards the egg trays, these can be recycled again to make more egg trays. This is the role model of environmentally responsibile manufacturing: https://pulpmouldingmachines.com/egg-tray-production-line/.