Overhead cranes in Kenya are used for various purposes, such as the following:

● Loading and unloading things from trucks

● Moving things from one place to another more efficiently than manpower or tow motor

● Moving items in an assembly line

● Feeding raw materials into the manufacturing machine

● Shifting containers in a railyard or shipyard

This type of crane is widely popular for lifting heavy objects from one place to another. For example, you will see overhead cranes indoors where they lift a container and place it on the deck of a ship. This may not have been possible with other machines. Most importantly, you can move such heavy items safely to your desired place.

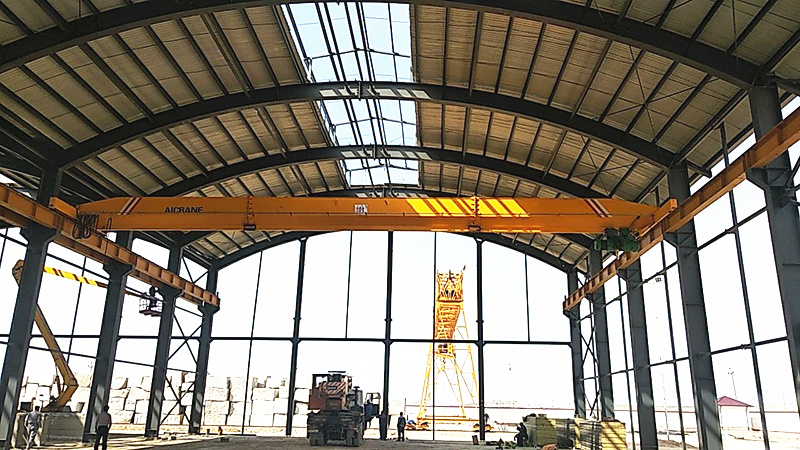

LD single girder overhead crane

Why use overhead cranes?

There are two reasons why you may need an overhead crane: safety and efficiency. These cranes can work faster than most land or floor-based devices. Moreover, in the case of any dangerous or hazardous working conditions, such as chemicals, toxic materials, or heated metals, an overhead crane Kenya can move your materials safely without putting your workers in danger.

Mechanism of overhead cranes

Using an overhead crane is more convenient when you have to move any bulky material. This type of crane works on a rectangular area and can move forward and backward as well as from side to side. It comes with various features, such as beams, trolleys, hoists, control systems, and girders. Here’s how the crane works:

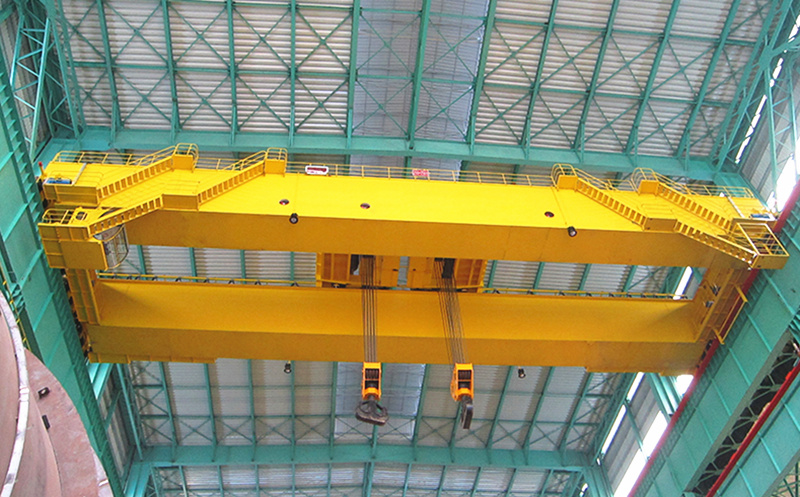

1. Bridge – The bridge runs longitudinally along the tracks on the runway beams. These bridges have steel girders that help in connecting the runways from one side of the girder to the other.

2. Lifting trolley – The lifting trolley has a motor, brake, drum, pulleys, and reducer to lift the heavy load from the ground and keep the item in the place you want. The motor is responsible for driving the rotating drum through the crane’s reducer and the chain or rope lowers the object when you want to put it down in your desired place.

double girder overhead crane

3. Driving mechanism – The driving mechanism has two parts: first is the long transmission which contains driving wheels and secondly, there is a separate motor that helps to drive each of the wheels individually.

4. Power supply – The power supply of the overhead crane controls the hoist and trolley. The conductor bar system in the monorail or runway of the crane works on multiple bridges. This means the power supply has to distribute its power through the sliding shoe collector system, making the entire process safer for everyone.

5. Height – There is a bearing on the motor that controls the overall height of the crane. The lift head covers the distance from one side of the floor to the other with the help of a saddle on the hook. The C dimension is another part that allows the crane to reach its maximum height.

These parts must work in tandem to ensure that the overhead crane can pick up heavy loads and unload the objects in the right places. Even the slightest malfunction of one of the parts may stop the crane from working smoothly.